Metal Fabrication

Making Beautiful and Useful Objects from Metal

With the right tools and knowledge, you can cut, shape, weld, forge, or machine metal into as many things as you can imagine. BARN’s Metal Fabrication studio has the instructors and tools to give you access to all these techniques.

Read on to learn more about what you can do in the three main metal shops: machine, welding and plasma, forge and foundry, and sheet metal shops. Each shop has a skilled team of monitors and instructors with many years of experience and know-how. With some instruction and practice, you’ll be ready to join our Open Studios and use the equipment on your own projects!

Getting Started in the Studio

- Stop in during a Tidy-Friday meetup or monthly Fix-It Open Studio.

- Register for a free Machine Shop Orientation.

- Take a beginner-friendly class.

Metal Fabrication Calendar

Welding: Open Studio for Plasma, Sheet Metal, and Welding

May 31, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

May 31, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

June 2, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

June 2, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Welding: Metal Side Table with Fused-Glass Top

June 3, 2025 1:00 pm - 3:30 pm

Glass Arts Studio and Welding & Sheet Metal Shop

Foundry: Pattern Making for Metal Casting

June 4, 2025 6:00 pm - 7:30 pm

Offsite: Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Foundry: Finishing Your Casting

June 5, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

June 7, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Bladesmithing a Wood Carving Knife

June 7, 2025 10:00 am - 4:00 pm

Offsite at Yori Seeger's Blacksmith Shop, 20224 Pond View Lane, Poulsbo, WA 98310

Forge: Open Studio for the Forge

June 7, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

BARN at Wayzgoose Kitsap

June 7, 2025 9:00 am - 5:00 pm

Offsite at Sheridan Park in Bremerton

Welding: Intro to Tungsten Inert Gas Welding (TIG #1)

June 8, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

June 9, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Welding: Metal Side Table with Fused-Glass Top

June 10, 2025 1:00 pm - 3:30 pm

Glass Arts Studio and Welding & Sheet Metal Shop

Collaboration! Metal and Mosaic Birds for the Yard

June 10, 2025 5:30 pm - 8:00 pm

Welding and Sheet Metal Shops and Glass Arts Studio

Forge: Fundamental Blacksmithing Skills

June 11, 2025 12:30 pm - 3:30 pm

Concrete Apron Outside BARN's Welding Shop

Foundry: Pattern Making for Metal Casting

June 11, 2025 6:00 pm - 7:30 pm

Offsite: Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Forge: Blacksmithing a Bottle Opener

June 12, 2025 10:00 am - 4:00 pm

Offsite at Yori Seeger's Blacksmith Shop: 20224 Pond View Lane, Poulsbo WA 98310

Foundry: Pattern Making for Metal Casting

June 12, 2025 6:00 pm - 7:00 pm

Offsite: Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

June 12, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Metal Fab Tidy-Friday

June 13, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

BARN at Bainbridge Juneteenth Celebration

June 13, 2025 5:00 pm - 8:00 pm

Offsite: Bainbridge Performing Arts and Town Square, 200 Madison Ave. N.

Collaboration! Metal and Mosaic Birds for the Yard

June 13, 2025 5:30 pm - 8:30 pm

Welding and Sheet Metal Shops and Glass Arts Studio

Metal Fabrication: Fix-It Saturday and Open Studio

June 14, 2025 10:00 am - 12:30 pm

Metal Machining, Welding, & Sheet Metal

Welding: Open Studio for Plasma, Sheet Metal, and Welding

June 14, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

June 14, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Layout and Cut Numbers with the CNC Plasma Cutter

June 15, 2025 12:00 pm - 4:00 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

June 16, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Welding: Metal Side Table with Fused-Glass Top

June 17, 2025 1:00 pm - 3:30 pm

Glass Arts Studio and Welding & Sheet Metal Shop

Welding: Metal Inert Gas Welding (MIG #2)

June 18, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Foundry: Casting Bronze in the Foundry

June 19, 2025 6:00 pm - 9:00 pm

Offsite: Monkey Wrench Foundry, 9392 Wardwell Ave. NE, Bainbridge Island

Welding: Open Studio for Plasma, Sheet Metal, and Welding

June 21, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

BARN at Bainbridge Pride

June 21, 2025 12:00 pm - 5:00 pm

Offsite at Bainbridge Island's Waterfront Park

Forge: Open Studio for the Forge

June 21, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: TIG Skills for Beginners and Beyond

June 22, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

June 23, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Foundry: Finishing Your Casting

June 26, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Metal Fab Tidy-Friday

June 27, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Welding: Open Studio for Plasma, Sheet Metal, and Welding

June 28, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Bladesmith a Sloyd Knife

June 28, 2025 10:00 am - 4:00 pm

Offsite at Yori Seeger's Blacksmith Shop, 20224 Pond View Lane, Poulsbo WA 98310

Forge: Open Studio for the Forge

June 28, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Forge: Demonstration and Barbecue

June 28, 2025 6:00 pm - 8:00 pm

Concrete Apron Outside BARN's Welding Shop

Forge: Bladesmith a Sloyd Knife

June 29, 2025 10:00 am - 4:00 pm

Offsite at Yori Seeger's Blacksmith Shop, 20224 Pond View Lane, Poulsbo WA 98310

Welding: Open Studio for Plasma, Sheet Metal, and Welding

June 30, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Foundry: Pattern Making for Metal Casting

July 2, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Welding: Open Studio for Plasma, Sheet Metal, and Welding

July 5, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

July 5, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Practical Brazing and Silver Soldering

July 6, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 7, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 7, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

July 7, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 8, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 8, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

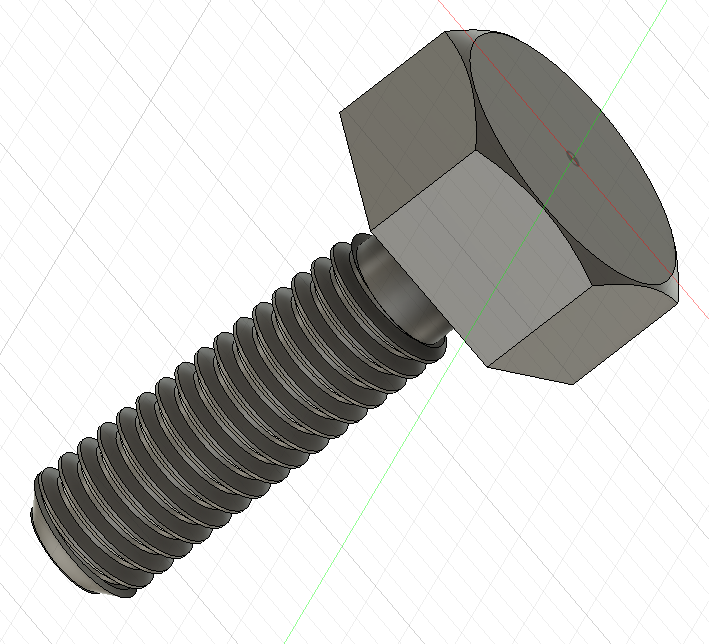

Machine Shop: Make a Bolt (Intro to the Lathe)

July 8, 2025 6:00 pm - 8:30 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 9, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 9, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Foundry: Pattern Making for Metal Casting

July 9, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 10, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 10, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Foundry: Pattern Making for Metal Casting

July 10, 2025 6:00 pm - 7:00 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Machine Shop: Make a Nut (Intro to the Mill)

July 10, 2025 6:00 pm - 9:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 11, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Metal Fab Tidy-Friday

July 11, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 11, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Metal Fabrication: Fix-It Saturday and Open Studio

July 12, 2025 10:00 am - 12:30 pm

Metal Machining, Welding, & Sheet Metal

Welding: Intro to Tungsten Inert Gas Welding (TIG #1)

July 13, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 14, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 14, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 15, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 15, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 16, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 16, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Welding: Metal Inert Gas Welding (MIG #2)

July 16, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 17, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 17, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Foundry: Casting Bronze in the Foundry

July 17, 2025 6:00 pm - 9:00 pm

Offsite at Monkey Wrench Foundry, 9392 Wardwell Ave. NE, Bainbridge Island

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 18, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 18, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

BARN at Peninsula Art League Summer Festival

July 19, 2025 10:00 am - 5:00 pm

Offsite: Sehmel Homestead Park, 10123 78th Ave. N.W., Gig Harbor WA 98332

Welding: Open Studio for Plasma, Sheet Metal, and Welding

July 19, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

July 19, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Layout and Cut Numbers with the CNC Plasma Cutter

July 20, 2025 12:00 pm - 4:00 pm

Welding & Sheet Metal Shop

BARN at Peninsula Art League Summer Festival

July 20, 2025 10:00 am - 5:00 pm

Offsite: Sehmel Homestead Park, 10123 78th Ave. N.W., Gig Harbor WA 98332

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 21, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 21, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 22, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 22, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 23, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 23, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 24, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 24, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Foundry: Finishing Your Casting

July 24, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 25, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Metal Fab Tidy-Friday

July 25, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 25, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Welding: Open Studio for Plasma, Sheet Metal, and Welding

July 26, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

July 26, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: TIG Skills for Beginners and Beyond

July 27, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 28, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 28, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 29, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 29, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 30, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 30, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 31, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

July 31, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

July 31, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 1, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Welding: Open Studio for Plasma, Sheet Metal, and Welding

August 2, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

August 2, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 4, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 4, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 5, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 5, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 6, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 6, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Foundry: Patternmaking for Metal Casting

August 6, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 7, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 7, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 8, 2025 9:00 am - 12:00 pm

Metal Fabrication Studio

Metal Fab Tidy-Friday

August 8, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Summer Youth: Weld a Metal Pet (Ages 10-14)

August 8, 2025 1:00 pm - 4:00 pm

Metal Fabrication Studio

Metal Fabrication: Fix-It Saturday and Open Studio

August 9, 2025 10:00 am - 12:30 pm

Metal Machining, Welding, & Sheet Metal

Forge: Open Studio for the Forge

August 9, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

August 11, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Foundry: Patternmaking for Metal Casting

August 13, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Foundry: Patternmaking for Metal Casting

August 14, 2025 6:00 pm - 7:00 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Welding: Open Studio for Plasma, Sheet Metal, and Welding

August 16, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

August 16, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Layout and Cut Numbers with the CNC Plasma Cutter

August 17, 2025 12:00 pm - 4:00 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

August 18, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Foundry: Casting Bronze in the Foundry

August 21, 2025 6:00 pm - 9:00 pm

Offsite: Monkey Wrench Foundry, 9392 Wardwell Ave. NE, Bainbridge Island

Metal Fab Tidy-Friday

August 22, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Welding: Open Studio for Plasma, Sheet Metal, and Welding

August 23, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

August 23, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

August 25, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Foundry: Finishing Your Casting

August 28, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

August 30, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

August 30, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Foundry: Patternmaking for Metal Casting

September 3, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

September 4, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

September 6, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

September 6, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Practical Brazing and Silver Soldering

September 7, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

September 8, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Machine Shop: Make a Hammer

September 9, 2025 6:00 pm - 9:00 pm

Metal Fabrication Studio

Foundry: Patternmaking for Metal Casting

September 10, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Foundry: Patternmaking for Metal Casting

September 11, 2025 6:00 pm - 7:00 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

September 11, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Machine Shop: Make a Hammer

September 11, 2025 6:00 pm - 9:00 pm

Metal Fabrication Studio

Metal Fab Tidy-Friday

September 12, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Metal Fabrication: Fix-It Saturday and Open Studio

September 13, 2025 10:00 am - 12:30 pm

Metal Machining, Welding, & Sheet Metal

Forge: Open Studio for the Forge

September 13, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Intro to Tungsten Inert Gas Welding (TIG #1)

September 14, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

September 15, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Welding: Metal Inert Gas Welding (MIG #2)

September 17, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Foundry: Casting Bronze in the Foundry

September 18, 2025 6:00 pm - 9:00 pm

Offsite at Monkey Wrench Foundry, 9392 Wardwell Ave. NE, Bainbridge Island

Welding: Open Studio for Plasma, Sheet Metal, and Welding

September 20, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

September 20, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Foundry: Finishing Your Casting

September 25, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Metal Fab Tidy-Friday

September 26, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Welding: Open Studio for Plasma, Sheet Metal, and Welding

September 27, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

September 27, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: TIG Skills for Beginners and Beyond

September 28, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

September 29, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

September 29, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Foundry: Patternmaking for Metal Casting

October 1, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Forge: Open Studio for the Forge

October 4, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

October 6, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Collaboration! Metal and Mosaic Art for the Yard

October 7, 2025 5:30 pm - 8:30 pm

Welding and Sheet Metal Shops and Glass Arts Studio

Foundry: Patternmaking for Metal Casting

October 8, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

October 9, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Foundry: Patternmaking for Metal Casting

October 9, 2025 6:00 pm - 7:00 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Metal Fab Tidy-Friday

October 10, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Collaboration! Metal and Mosaic Art for the Yard

October 10, 2025 5:30 pm - 8:00 pm

Welding and Sheet Metal Shops and Glass Arts Studio

Metal Fabrication: Fix-It Saturday and Open Studio

October 11, 2025 10:00 am - 12:30 pm

Metal Machining, Welding, & Sheet Metal

Forge: Open Studio for the Forge

October 11, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Intro to Tungsten Inert Gas Welding (TIG #1)

October 12, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

October 13, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Machine Shop: Make a Bolt (Intro to the Lathe)

October 14, 2025 6:00 pm - 8:30 pm

Metal Fabrication Studio

Welding: Metal Inert Gas Welding (MIG #2)

October 15, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Machine Shop: Make a Nut (Intro to the Mill)

October 16, 2025 6:00 pm - 9:00 pm

Metal Fabrication Studio

Foundry: Casting Bronze in the Foundry

October 16, 2025 6:00 pm - 9:00 pm

Offsite at Monkey Wrench Foundry, 9392 Wardwell Ave. NE, Bainbridge Island

Welding: Open Studio for Plasma, Sheet Metal, and Welding

October 18, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

October 18, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Layout and Cut Numbers with the CNC Plasma Cutter

October 19, 2025 12:00 pm - 4:00 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

October 20, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Foundry: Finishing Your Casting

October 23, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Metal Fab Tidy-Friday

October 24, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Welding: Open Studio for Plasma, Sheet Metal, and Welding

October 25, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

October 25, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: TIG Skills for Beginners and Beyond

October 26, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

October 27, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Welding: Open Studio for Plasma, Sheet Metal, and Welding

November 1, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

November 1, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

November 3, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

November 3, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Foundry: Patternmaking for Metal Casting

November 5, 2025 6:00 pm - 7:30 pm

Offsite: Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Metal Fabrication: Fix-It Saturday and Open Studio

November 8, 2025 10:00 am - 12:30 pm

Metal Machining, Welding, & Sheet Metal

Forge: Open Studio for the Forge

November 8, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Intro to Tungsten Inert Gas Welding (TIG #1)

November 9, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

November 10, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Machine Shop: Make a Bolt (Intro to the Lathe)

November 11, 2025 6:00 pm - 8:30 pm

Metal Fabrication Studio

Foundry: Patternmaking for Metal Casting

November 12, 2025 6:00 pm - 7:30 pm

Offsite: Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

November 13, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Foundry: Patternmaking for Metal Casting

November 13, 2025 6:00 pm - 7:00 pm

Offsite: Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Machine Shop: Make a Nut (Intro to the Mill)

November 13, 2025 6:00 pm - 9:00 pm

Metal Fabrication Studio

Metal Fab Tidy-Friday

November 14, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Welding: Open Studio for Plasma, Sheet Metal, and Welding

November 15, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

November 15, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Layout and Cut Numbers with the CNC Plasma Cutter

November 16, 2025 12:00 pm - 4:00 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

November 17, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Welding: Metal Inert Gas Welding (MIG #2)

November 19, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Foundry: Casting Bronze in the Foundry

November 20, 2025 6:00 pm - 9:00 pm

Offsite at Monkey Wrench Foundry, 9392 Wardwell Ave. NE, Bainbridge Island

Welding: Open Studio for Plasma, Sheet Metal, and Welding

November 22, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

November 22, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: TIG Skills for Beginners and Beyond

November 23, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

November 24, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Foundry: Finishing Your Casting

November 27, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Metal Fab Tidy-Friday

November 28, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Welding: Open Studio for Plasma, Sheet Metal, and Welding

November 29, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

November 29, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

December 1, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Welding: Introduction to Metal Inert Gas Welding (MIG #1)

December 1, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Welding: Practical Brazing and Silver Soldering

December 2, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Foundry: Patternmaking for Metal Casting

December 3, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Welding: Open Studio for Plasma, Sheet Metal, and Welding

December 6, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

December 6, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

December 8, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Foundry: Patternmaking for Metal Casting

December 10, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Foundry: Patternmaking for Metal Casting

December 11, 2025 6:00 pm - 7:00 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

Metal Fab Tidy-Friday

December 12, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Metal Fabrication: Fix-It Saturday and Open Studio

December 13, 2025 10:00 am - 12:30 pm

Metal Machining, Welding, & Sheet Metal

Forge: Open Studio for the Forge

December 13, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Intro to Tungsten Inert Gas Welding (TIG #1)

December 14, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

December 15, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Welding: Metal Inert Gas Welding (MIG #2)

December 17, 2025 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

Foundry: Casting Bronze in the Foundry

December 18, 2025 6:00 pm - 9:00 pm

Offsite at Monkey Wrench Foundry, 9392 Wardwell Ave. NE, Bainbridge Island

Welding: Open Studio for Plasma, Sheet Metal, and Welding

December 20, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

December 20, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: Layout and Cut Numbers with the CNC Plasma Cutter

December 21, 2025 12:00 pm - 4:00 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

December 22, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

Metal Fab Tidy-Friday

December 26, 2025 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

Welding: Open Studio for Plasma, Sheet Metal, and Welding

December 27, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio

Forge: Open Studio for the Forge

December 27, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

Welding: TIG Skills for Beginners and Beyond

December 28, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

Welding: Open Studio for Plasma, Sheet Metal, and Welding

December 29, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

- June 30, 2025

-

-

Welding: Open Studio for Plasma, Sheet Metal, and Welding

June 30, 2025 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

- July 2, 2025

-

-

Foundry: Pattern Making for Metal Casting

July 2, 2025 6:00 pm - 7:30 pm

Offsite at Jeff Oens Studio, 8893 Three Tree Lane, Unit #1, Bainbridge Island, WA, 98110

-

- July 5, 2025

-

-

Welding: Open Studio for Plasma, Sheet Metal, and Welding

July 5, 2025 10:00 am - 12:30 pm

Welding & Sheet Metal Studio -

Forge: Open Studio for the Forge

July 5, 2025 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

- July 6, 2025

-

-

Welding: Practical Brazing and Silver Soldering

July 6, 2025 2:00 pm - 4:30 pm

Welding & Sheet Metal Shop

-

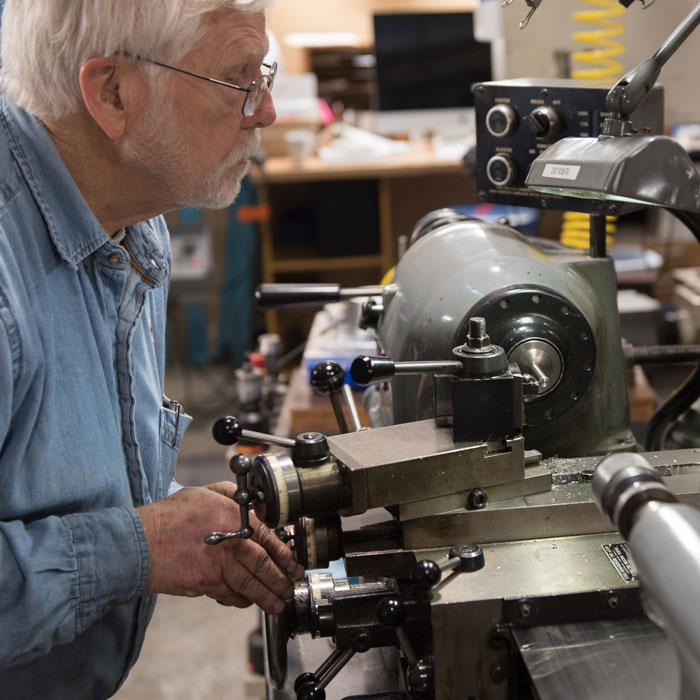

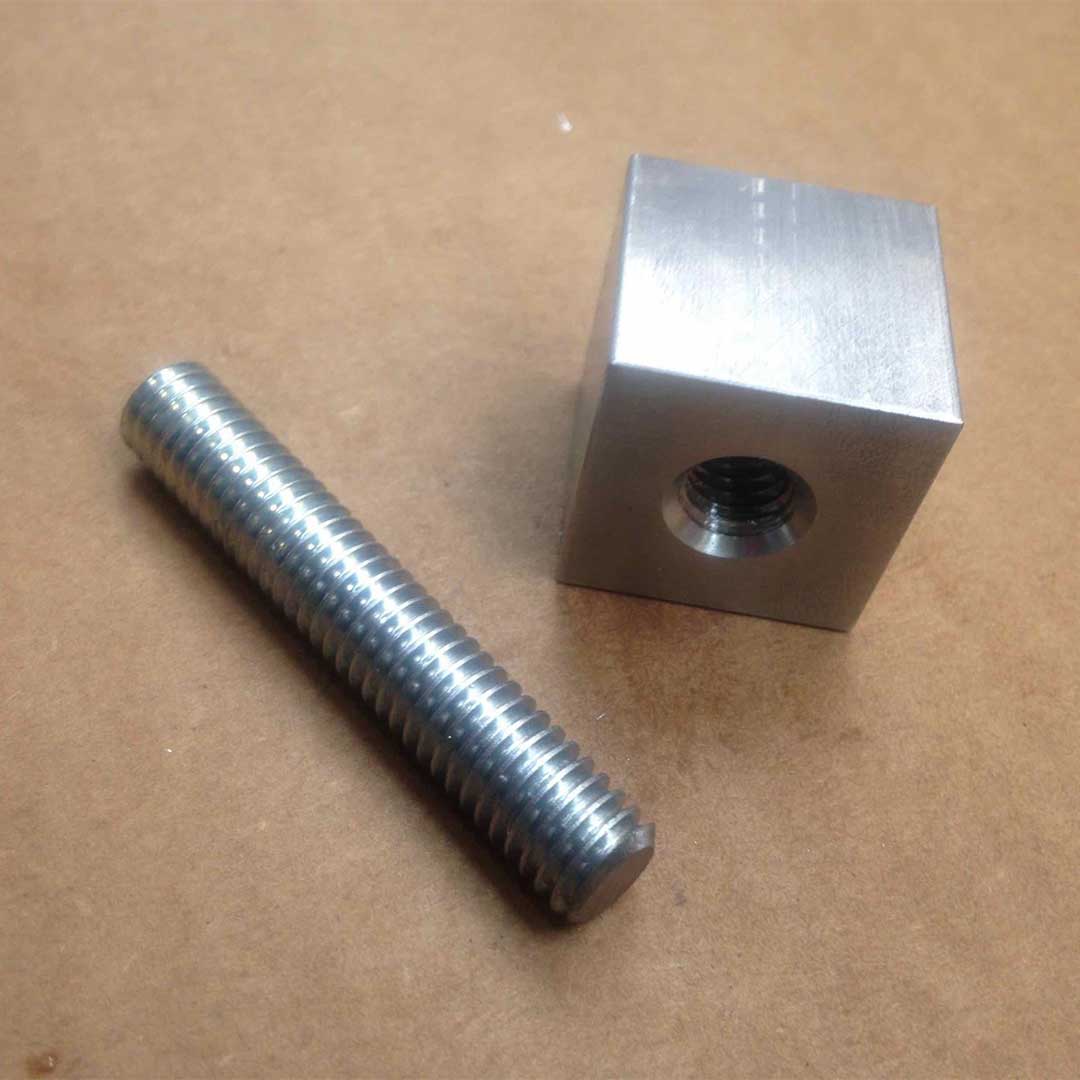

Machining

Often used on metal, machining is a process in which a material is cut, drilled, or milled to precise specifications using specialized machines. BARN’s well-equipped Machine Shop can be used to repair parts, fabricate new parts, or 3D-print a component. The machines are controlled either manually or by CNC (computer numerical control).

As important as the machines are, the experience of imagining solutions to challenging problems is an activity eagerly engaged and shared by BARN’s Metal Fabrication community. If you’ve a specific challenge, drop by the Machine Shop and engage one of the Monitors; they’ll work to help you come up with a solution.

Sheet Metal

Sheets of metal can be cut, shaped, and bonded together in this multi-function shop. Cutting and shaping can be done with hand tools, as well as larger machines such as pan brakes, shears, slip rolls, and English wheels, all of which we have in our sheet metal shop. Project-oriented classes can build skills by making household items, automotive parts, or freestyle art.

Welding and Plasma Cutting

BARN’s focus is on two primary welding processes: MIG and TIG. MIG (Metal Inert Gas) welding is the easiest to learn and the most versatile. It has wide application from garden art to furniture to structures. TIG (Tungsten Inert Gas) welding is more challenging but is more versatile as many types of metal can be welded, not just steel or aluminum.

Plasma Cutting is a technique of cutting electrically conductive metals (steel, stainless steel, aluminum, brass, titanium, and copper), both thick and thin. The plasma torch can be controlled manually or through CNC (computer numeric control) to make precision cuts through metal.

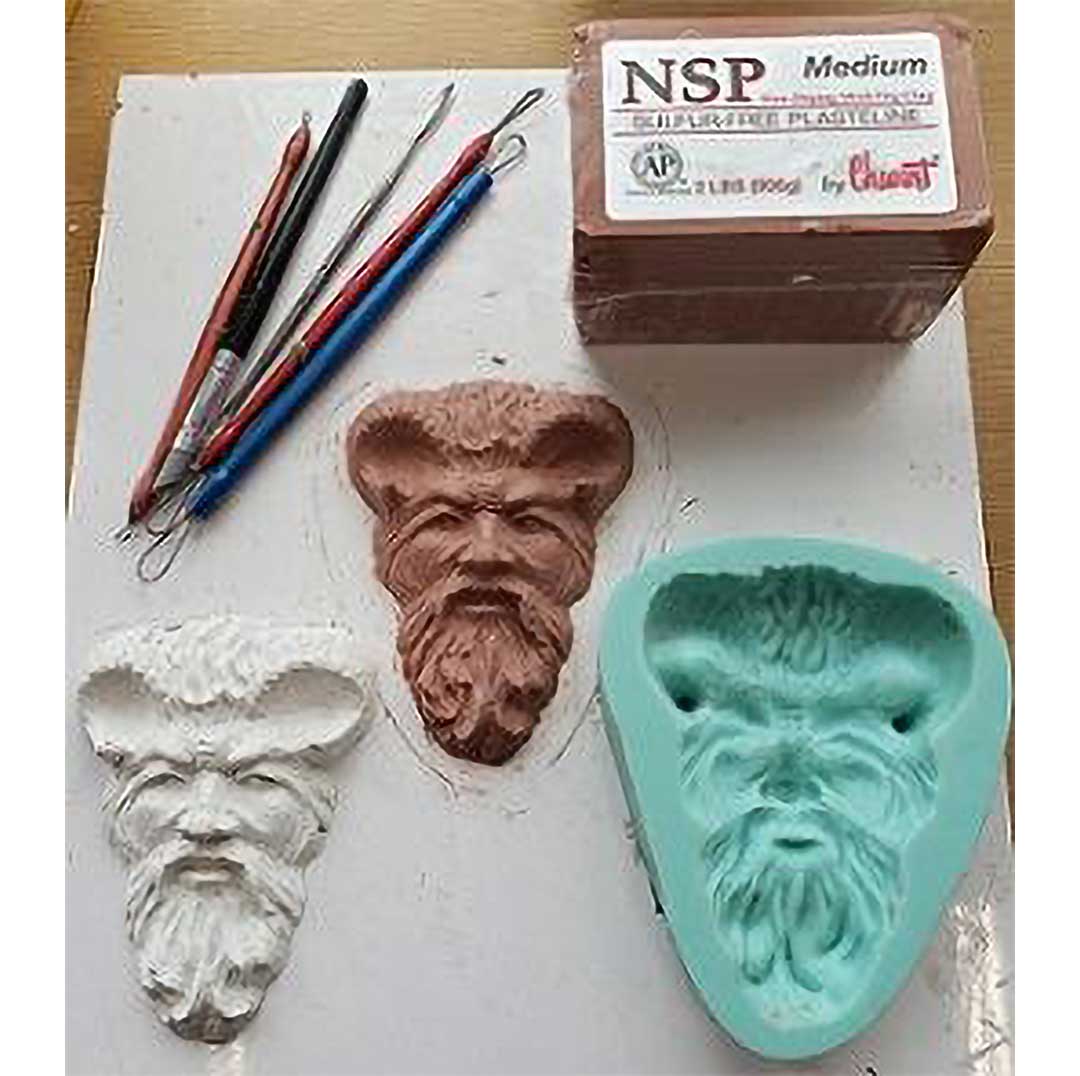

Foundry & Forge

A foundry uses a furnace to melt metal that is then poured into forms, creating objects of both art and utility. BARN’s melt furnace and casting events are held off site, while the pattern-making and finishing classes are conducted at BARN’s main facility. With the guidance of experienced instructors, participants learn the basic skills of sand casting – pattern making, molding, pouring, and finishing. Breaking a fresh casting out of a cooling form is a true joy to experience.

Blacksmithing or forging is the process of heating metal in a forge, then forming that hot metal with anvil, hammer and tongs. This artisanal craft has evolved from an essential skill of the Iron Age through Colonial times to modern-day art. BARN is working to further develop its Forge program from basic to advanced skills in blacksmithing. It’s a great way to experience a small part of our ancestors’ lives.

Upcoming Metal Fabrication Events

-

-

Metal Fabrication:

Foundry: Patternmaking for Metal Casting (1st of 3 Foundry classes)

Jul 2, 2025 6:00pm -

-

-

-

-

-

-

Open Studio

Work on your own projects after attending a studio orientation. Learn more »

FAQ

Wondering where to start in the Metal Fabrication Studio? Read our FAQ »

Volunteer

Volunteers keep our studio running smoothly. View opportunities »

Metal Fabrication Resources

Join our Facebook group

Join our community on BARN Circle

Contact Us

Message us using our form

Metal Fabrication office phone: 206-842-4475 x207

Andy Dupree

Andy Dupree

Andy Dupree is a harpsichord maker, professional woodworker, and business consultant based on Bainbridge Island. Originally working as an organ builder in Ohio, he later trained as a harpsichord maker before opening his own shop. He has built instruments for such institutions as the Eastman School of Music and the Oberlin Conservatory of Music. Andy moved to the Northwest, working for Microsoft before turning to management and leadership consulting. Over the last few years, he has honed his machinist skills and focuses on tool-making and building small steam engines.

Metal Fabrication Studio Lead

Metal Fabrication News

Metal: Restoration of the Maypole Braider

Hey, all you Metal-Fabbers, here’s your October edition of the Metal-Fab newsletter. Restoration of the Maypole Braider We finished several projects as summer came to a close. ...Full story »

Facilities Updates: Barn Doors, New Tables

Volunteers from BARN's Woodworking & Small Boatbuilding and Metal Fabrication studios have been sprucing up the building’s common areas. You may have noticed the beautiful new "barn doors" ...Full story »

Community Service: Prayer Wheel Restoration

Volunteers from BARN's Metal Fabrication Studio are hard at work repairing the bronze prayer wheel from Bainbridge Island's Halls Hill Lookout. A broken component was preventing the ...Full story »

.jpg)

Follow Us