Making Beautiful and Useful Objects from Metal

With the right tools and knowledge, you can cut, shape, weld, forge, or machine metal into as many things as you can imagine. BARN’s Metal Fabrication studio has the instructors and tools to give you access to all these techniques.

Read on to learn more about what you can do in the three main metal shops: machine, welding and plasma, forge and foundry, and sheet metal shops. Each shop has a skilled team of monitors and instructors with many years of experience and know-how. With some instruction and practice, you’ll be ready to join our Open Studios and use the equipment on your own projects!

Getting Started in the Studio

Metal Fabrication Calendar

- February 23, 2026

-

-

Welding: Open Studio for Plasma, Sheet Metal, and Welding

February 23, 2026 1:00 pm - 3:30 pm

Welding & Sheet Metal Studio

- February 24, 2026

-

-

Youth: Weld a Tension Table Series (Ages 12-16)

February 24, 2026 4:00 pm - 6:00 pm

Welding Shop

-

- February 25, 2026

-

- February 26, 2026

-

-

Foundry: Finishing Your Casting

February 26, 2026 6:00 pm - 8:30 pm

Welding & Sheet Metal Shop

-

- February 27, 2026

-

-

Metal Fab Tidy-Friday

February 27, 2026 10:00 am - 12:00 pm

Metal Machining, Welding, & Sheet Metal

-

- February 28, 2026

-

-

Welding: Open Studio for Plasma, Sheet Metal, and Welding

February 28, 2026 10:00 am - 12:30 pm

Welding & Sheet Metal Studio -

Forge: Open Studio for the Forge

February 28, 2026 12:00 pm - 3:00 pm

Concrete Apron Outside BARN's Welding Shop

- March 1, 2026

-

Machining

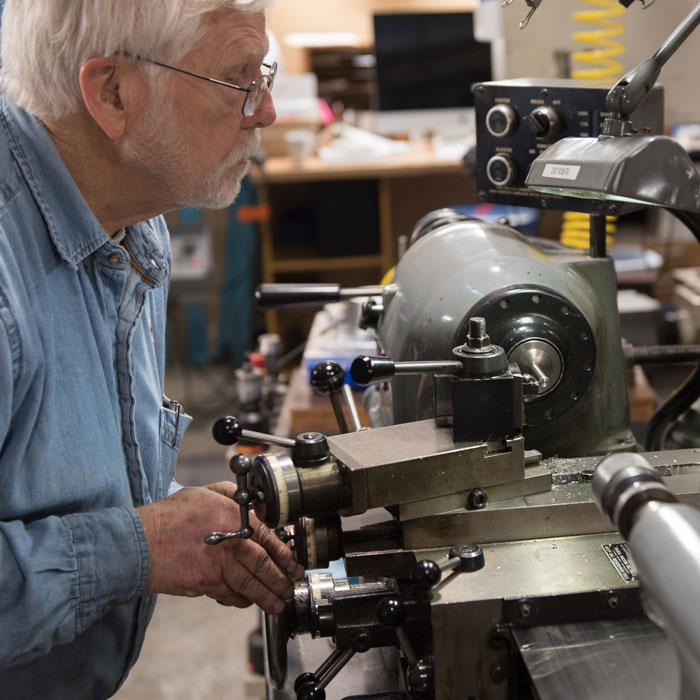

Often used on metal, machining is a process in which a material is cut, drilled, or milled to precise specifications using specialized machines. BARN’s well-equipped Machine Shop can be used to repair parts, fabricate new parts, or 3D-print a component. The machines are controlled either manually or by CNC (computer numerical control).

As important as the machines are, the experience of imagining solutions to challenging problems is an activity eagerly engaged and shared by BARN’s Metal Fabrication community. If you’ve a specific challenge, drop by the Machine Shop and engage one of the Monitors; they’ll work to help you come up with a solution.

Sheet Metal

Sheets of metal can be cut, shaped, and bonded together in this multi-function shop. Cutting and shaping can be done with hand tools, as well as larger machines such as pan brakes, shears, slip rolls, and English wheels, all of which we have in our sheet metal shop. Project-oriented classes can build skills by making household items, automotive parts, or freestyle art.

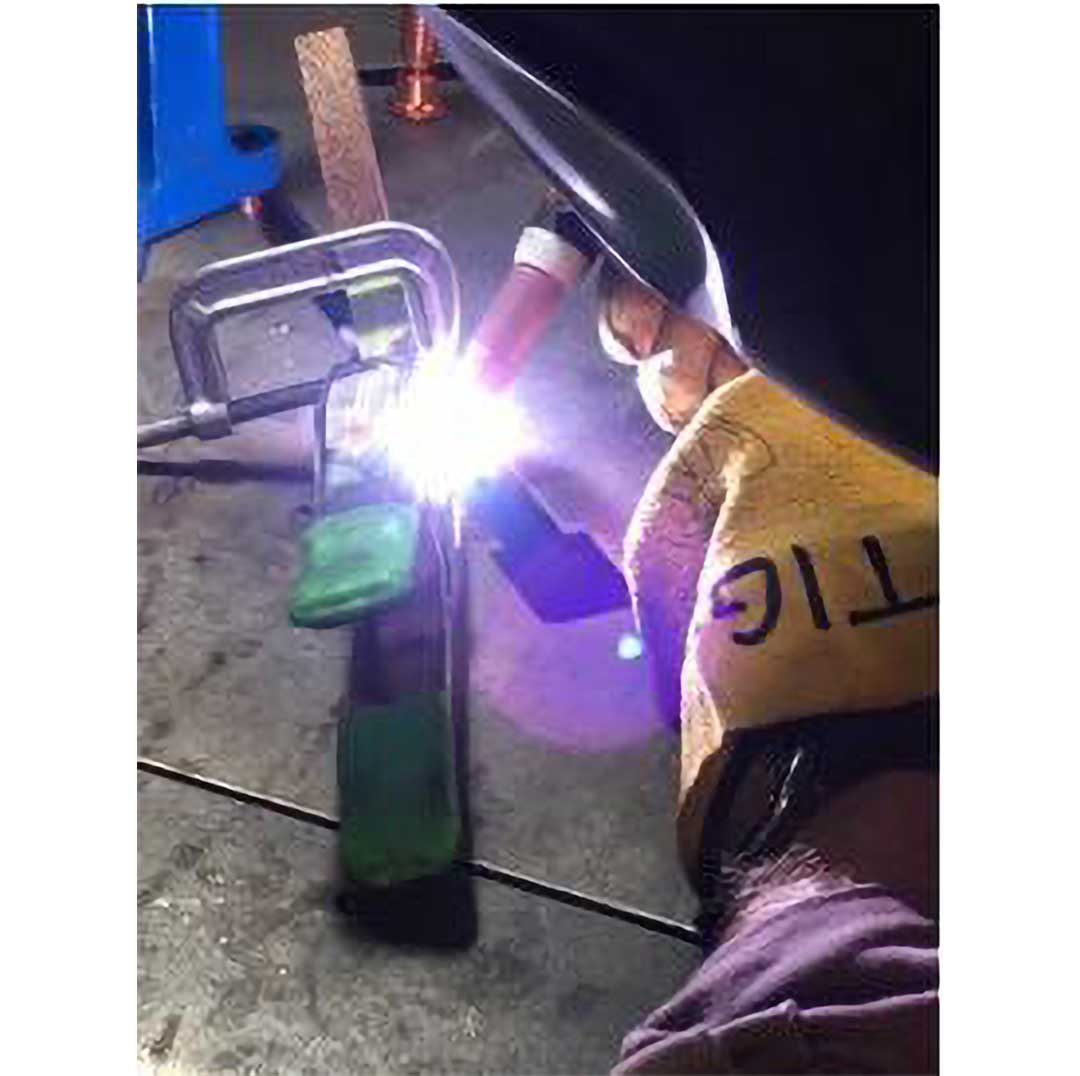

Welding and Plasma Cutting

BARN’s focus is on two primary welding processes: MIG and TIG. MIG (Metal Inert Gas) welding is the easiest to learn and the most versatile. It has wide application from garden art to furniture to structures. TIG (Tungsten Inert Gas) welding is more challenging but is more versatile as many types of metal can be welded, not just steel or aluminum.

Plasma Cutting is a technique of cutting electrically conductive metals (steel, stainless steel, aluminum, brass, titanium, and copper), both thick and thin. The plasma torch can be controlled manually or through CNC (computer numeric control) to make precision cuts through metal.

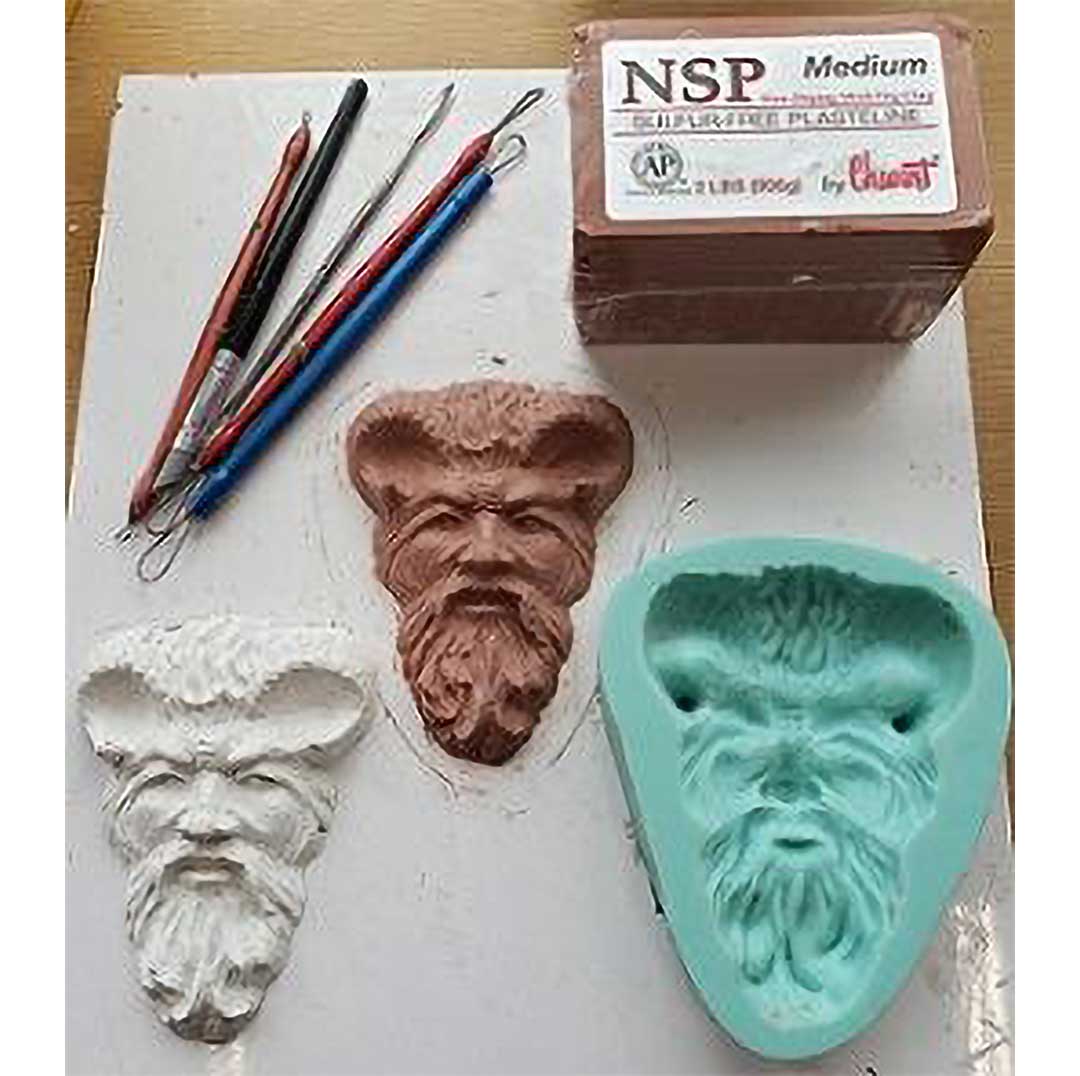

Foundry & Forge

A foundry uses a furnace to melt metal that is then poured into forms, creating objects of both art and utility. BARN’s melt furnace and casting events are held off site, while the pattern-making and finishing classes are conducted at BARN’s main facility. With the guidance of experienced instructors, participants learn the basic skills of sand casting – pattern making, molding, pouring, and finishing. Breaking a fresh casting out of a cooling form is a true joy to experience.

Blacksmithing or forging is the process of heating metal in a forge, then forming that hot metal with anvil, hammer and tongs. This artisanal craft has evolved from an essential skill of the Iron Age through Colonial times to modern-day art. BARN is working to further develop its Forge program from basic to advanced skills in blacksmithing. It’s a great way to experience a small part of our ancestors’ lives.

Upcoming Metal Fabrication Events

Open Studio

Work on your own projects after attending a studio orientation. Learn more »

FAQ

Wondering where to start in the Metal Fabrication Studio? Read our FAQ »

Volunteer

Volunteers keep our studio running smoothly. View opportunities »

Metal Fabrication Resources

Join our Facebook group

Join our community on BARN Circle

Contact Us

Message us using our form

Metal Fabrication office phone: 206-842-4475 x207

Andy Dupree

Metal Fabrication Studio Lead

Metal Fabrication News

21st Century Design Exhibition Open Now

On display from now until April in BARN's Commons: 21st Century Design!

January Metal Fab Update

Hey all you Metal-Fabbers, welcome to 2026, the year we celebrate the 250th anniversary of the signing of the Declaration of Independence. The year is also an excellent marker to celebrate American handwork and craft. That's what BARN's Handwork Week 2026 is all about: celebrating what BARN is and our creative craft.

HANDWORK: Bringing Bronze to Life With the BARN Foundry Team

Monkey Wrench Fabrication on Wardwell Avenue is adorned with vintage signs and found metal objects, a fitting detail for a craft that has transformed ...Full story »

Follow Us